About NMB Technologies Corporation

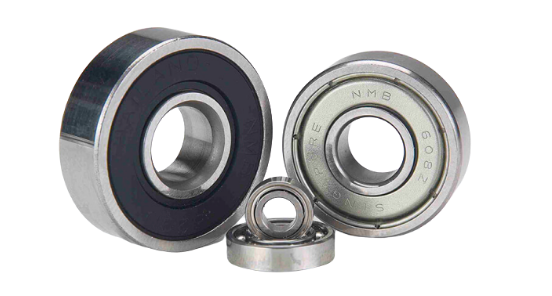

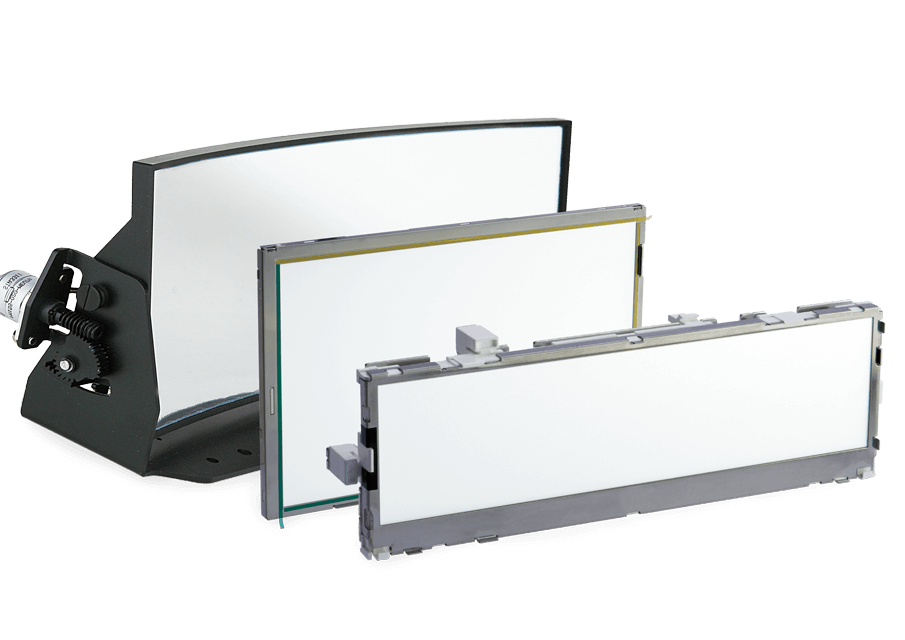

NMB Technologies Corporation is a MinebeaMitsumi Group company; the world’s largest manufacturer of NMB miniature ball bearings and a volume leader in the design and manufacturing of precision electromechanical and semiconductor components such as small motors, backlights, sensors and wireless technology. We provide advanced technology solutions for the automotive, robotics, medical, consumer technology, industrial, and smart city markets.

Our Company

NMB Technologies Corporation, a MinebeaMitsumi Group Company, is headquartered in Novi, Michigan, with offices in San Jose, CA, Chatsworth, CA, Boston, MA, Boulder, CO, and Seattle, WA. We offer Sales, Customer Service, Engineering, Quality, and Administrative support for all MinebeaMitsumi products in North America. Our expert Account Managers and Application Engineers work closely with our customers to create solutions tailored for Automotive, Consumer Technology, Industrial, Medical, Smart City, and Lighting products. We work closely with our sister company, NMB-Minebea de Mexico in Queretaro, Mexico, to provide support across North America.

NMB (USA) Inc.

NMB (USA) Inc., located in Chatsworth California, is the headquarters for MinebeaMitsumi’s North American Group of Companies. NMB (USA) Inc. was created in 1984 as a holding company to manage MinebeaMitsumi’s United States subsidiaries: NMB Technologies Corporation and New Hampshire Ball Bearings, Inc.

New Hampshire Ball Bearings

New Hampshire Ball Bearings, Inc. (NHBB) is a leading manufacturer of precision bearings and complex bearing assemblies for the aerospace, defense, medical, dental, and high technology markets. NHBB’s diverse product mix includes precision miniature and instrument ball bearings, large ball and roller bearings for aircraft engines, and specialized rod end and spherical bearings for diverse aircraft applications. The company operates three manufacturing facilities in the US and employs over 1,500 workers. Founded in Peterborough, NH in 1946, NHBB was purchased in 1985 by the global manufacturing conglomerate, MinebeaMitsumi.

MinebeaMitsumi

As a company with its origins in the business of machined components including ball bearings as well as rod end bearings and pivot assemblies for aircraft, MinebeaMitsumi has expanded the business arena for motors, lighting devices, measuring components and other electronic devices. With production and sales bases in Japan, Thailand, China, the Philippines, and countries all over Asia as well as Europe and the Americas, MinebeaMitsumi today is a global corporation employing 100,000 people world wide. From the smartphone in the palm of your hand to the HALCA satellite’s rocket, MinebeaMitsumi’s products have a wide array of applications in our homes, offices, and the industrial world.

Our Values

High Performance

We are committed to excellence, to strategic effectiveness and to operational efficiency. NMB is dedicated to nurture the skills of our people, the innovation of our products, and the passion, inspiration and excellence that we bring to our customers.

Customer Support

NMB’s highest priority will always be to create strong, lasting partnerships with our customers by providing the highest quality products and services possible. Highly trained and experienced team members are dedicated to ensure that our customers are involved and informed every step of the way.

Teamwork

We are committed to working together in pursuit of common goals. Our teamwork is based on personal accountability, interpersonal communication and caring for one another. We promote and encourage cooperation and respect. We build strong teams with a clear purpose of finding solutions for our customers.

Integrity

Good customer service, respect for the individual, firm commitment to excellence and teamwork all depend on the basic belief that the Company and each of its employees must always act ethically and operate with integrity. We are dedicated to compliance with our policies and applicable regulations.

Commitment to Quality

MinebeaMitsumi is a name synonymous with high quality. Building a reputation with our customers that is centered on trust is fundamental to our business. Our core development process focuses on vertically integrated manufacturing which ensures complete control over the entire operation from design to mass production. MinebeaMitsumi manufactures most production and assembly equipment in-house, such as dies and jigs, that enhances both product quality and productivity at our factories. We also employ state-of-the-art analytical testing equipment to identify potential problems early and implement solutions that can be applied promptly and effectively on the production floor.

Our Team

Richard LaPlace

President

As President at NMB Technologies, Rich promotes close collaboration with our customers in order to develop the best solutions possible for each application. Rich is a strong advocate for doing business with integrity – an essential quality at NMB. He has been part of the NMB family since 1998 and continuously strives to make our company a great place to work.

Kotaro Torii

Vice President

Torii values the diverse and collaborative work environment at NMBTC. A true team player, he strives to align our product and sales strategies with MinebeaMitsumi’s global sustainability objectives. He enjoys facing challenges head-on and strongly believes “Where there is a will, there is a way”.

Tomohiro Takahashi

Director

Tomohiro brings a wealth of global experience and positive energy to the executive team at NMBTC. His history working with industry-leading Consumer Electronics and Automotive customers generates new opportunities for sales. He applies his love for cooking to continuously strive for the optimal “recipe” to solve our customer’s challenges.

Juanita Peña-Garcia

Human Resources Director

Juanita’s extensive HR experience helps expand business through significant change such as understanding of external threats and prospects, and transforming those into actions that mitigate risk and leverage opportunities. As a trusted and engaged leader of people and culture, she is able to forecast human capital demands by strategizing upskill personnel initiatives for future business needs.

Christian Voegerl

Director - Automotive Sales

Christian enjoys the small company vibe at NMB while having the support and resources of a multinational corporation. He understands the importance of providing first-class support to our Automotive customers from initial design concept through end of production.

Phil Olsen

Sales Director

Phil believes in engaging with our customers early in the development process. After 20+ years with NMB, Phil is an expert at creating the best solutions for our customers, from our extensive set of products, capabilities, and technical resources. He knows how we can help, and he knows how to make it happen.

Sustainability

Initiatives for Reducing Impacts on the Environment

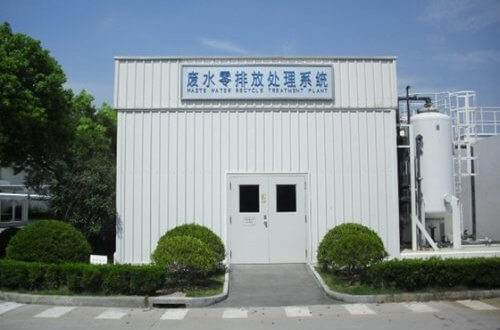

Plant Wastewater Purification

Prior to releasing wastewater into rivers, MinebeaMitsumi Group plants use their own processing equipment to purify it within fixed environmental standards. These plants adhere to environmental laws of the countries and localities in which they operate, and independently monitor such wastewater discharges, including regular testing for such metrics as pH1, COD2, BOD3, SS4, and n-hexane extracts5.

Observation of Waste Disposal Sites (Japan, Thailand)

Some waste material generated at plants and offices can be difficult to reuse or recycle at the plant or office. This type of waste material is outsourced to waste treatment companies for processing.

The MinebeaMitsumi Group selects reliable treatment companies for outsourcing processing and periodically visits the processing sites to observe the status of processing and management. We will continue to cooperate with treatment companies and take measures to prevent environmental contamination including soil, water, and air pollution during waste processing.

Operation of Plant Wastewater Zero System (Thailand & China)

The MinebeaMitsumi Group operates plants which use large amounts of water in the processing of manufactured products and take measures to reduce emissions of wastewater.

Our plants purify used water to reduce the level of waste to below standards required by each country and locality before releasing the water into the environment. Despite these measures, we cannot guarantee that the released water has zero impact on the surrounding environment.

At our plants in Thailand and China, which use large amounts of water, we have adopted the “Plant Wastewater Zero System” to reduce to as close to zero as possible the wastewater released and its impact on the environment.

In this system, the plants further purify wastewater that was previously treated and released into the environment, and then reuse the entire amount of wastewater internally at the plant without any external emissions.

Currently, this system is being used by the Bang Pa-in, Ayutthaya and Lop Buri plants in Thailand, as well as the Shanghai and Xicen plants in China.

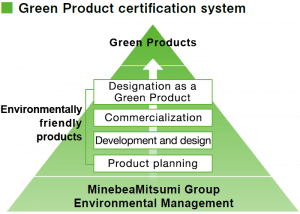

Green Products Certification Program

Our group has contributed to energy conservation activities in a wide range of industries, including the automotive industry and the aviation industry, by producing small, light and precise components. In order to visualize the environmental and social contributions of our products and to share their value with our stakeholders, we reported it to the Board of Directors in May 2019, and in the fiscal year ended March 2020, we started to introduce the MinebeaMitsumi Green Products Certification Program. We use our own indicators to certify items with high environmental contribution value. In the fiscal year ending March 2029, we plan to raise the ratio of Green Products sales to net sales to 85% or more.

Social Responsibility in Local Communities

As an enterprise operating on a global scale, MinebeaMitsumi Group believes in the importance of building sound partnerships with local communities through good communication. To establish firm roots in those communities, we carry out social contribution activities meeting local needs based upon our company credo “The Five Principles.”

By continuing to make active contributions to local communities in and outside Japan, the MinebeaMitsumi Group will strive to be an organization which deepens its community roots and expands sustainably with local communities.