Have a question about this product?

Ask Our Experts

Ask Our Experts

Motor Resolvers

A resolver is a type of rotation angle sensor for controlling the drive motor – the power source of electric vehicles. By efficiently controlling the motor, power consumption can be suppressed. To control the motor according to various driving conditions of a vehicle, it is necessary to detect the magnetic pole position of the motor, and accurately grasp its rotational speed. The resolver serves as the sensor for these tasks.

Features:

- Custom designed, in-house component manufacturing

- High accuracy and reliability

- Heat and oil resistant

- Superior wire winding and stamping technology

- Brushless Resolver

Applications:

- Electric powered steering

- Hybrid/electric vehicles

- Integrated starter alternators

- Brake/steer by wire

- Valve controls

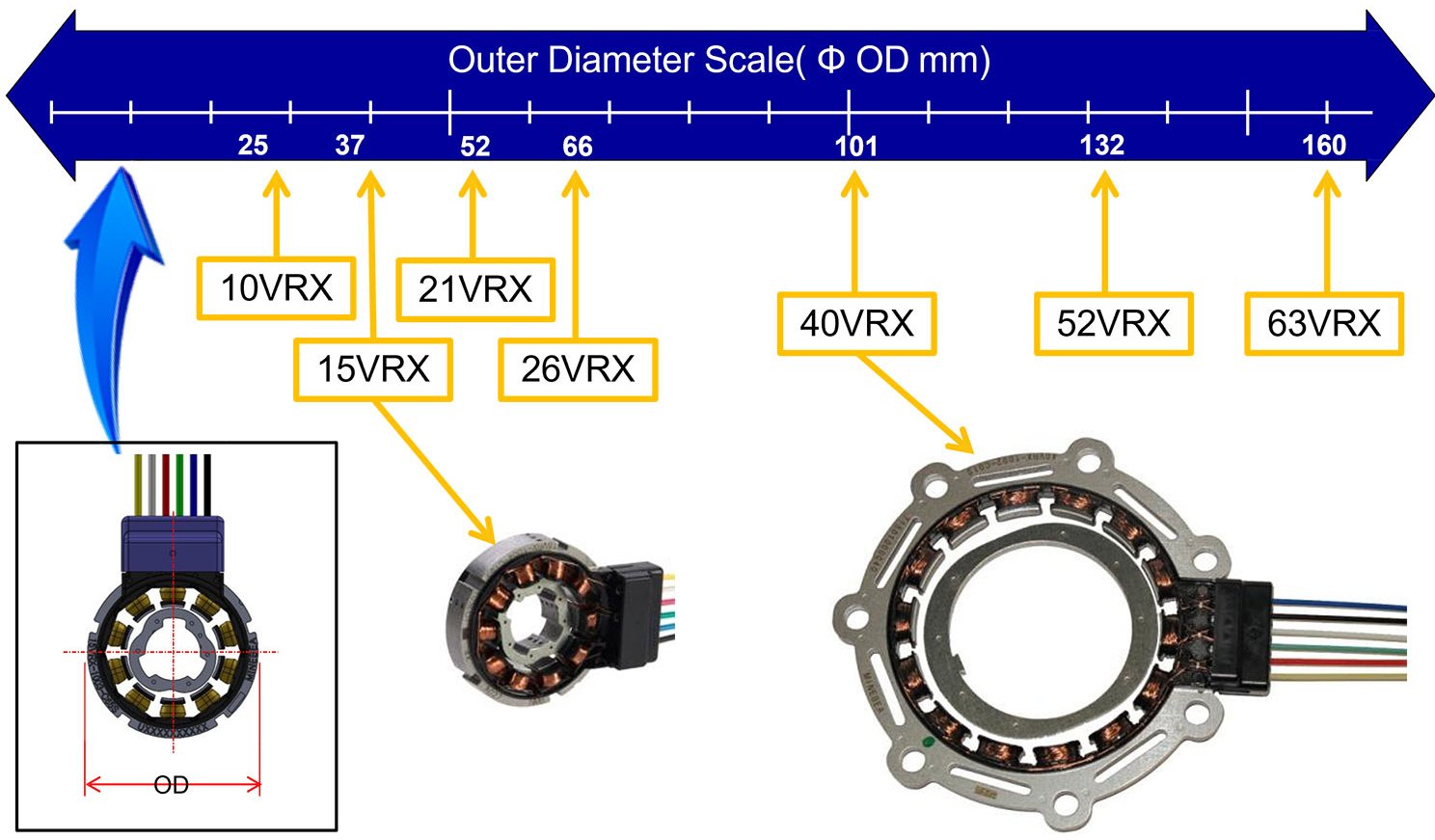

Range of Common Sizes

Characteristics of Common Sizes

Model | Stator Outer | Rotor Inner | Number of | Maximum | Stack | Transformation | Temperature | Data Sheet |

10VRX | 25 | 6 | 2X-4X | 30000 | 7 | 0.286±10 | -40 to +125 | |

15VRX | 37 | 12 | 2X-5X | 30000 | 7 | 0.286±10 | -40 to +125 | |

21VRX | 52 | 18 | 2X-8X | 30000 | 7 | 0.286±10 | -40 to +125 | |

26VRX | 66 | 30 | 2X-8X | 30000 | 7 | 0.286±10 | -40 to +125 | |

40VRX | 101 | 45 | 2X-6X | 12,000 | 4 | 0.286±10 | -40 to +125 | |

52VRX | 132 | 52 | 2X-6X | 12,000 | 4 | 0.286±10 | -40 to +125 | |

63VRX | 160 | 93 | 2X-6X | 12,000 | 4 | 0.286±10 | -40 to +125 |

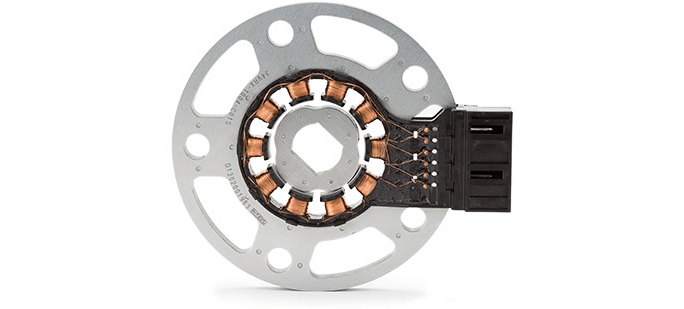

Our 40VRX and 21VRX size resolvers are largely spread through the market and compatible with a wide range of variation for rotor designs.

Possible Options & Customization

- Lead wire assembly with connector

- Built-in connector

- Rotor inner diameter adjusted to match shaft

- Keying feature on rotor

- Coating/surface treatment on the rotor/stator stack

- Outer rotor type

- Several options for Rotor Lobes

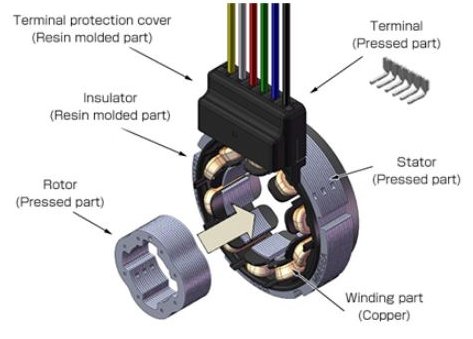

MinebeaMitsumi Resolver Manufacturing Technologies

Technologies cultivated in the production of rotary components and machined components are incorporated cross-sectional in the resolver, ranging from the electromagnetic technology and winding technology to the stamping technology. MinebeaMitsumi produces high precision resolvers by combining multiple technologies that only a comprehensive precision equipment manufacture can achieve.

Winding technology that influences position detection accuracy

One of the parts that greatly influence the accuracy of a resolver is the winding provided in a stator. The angle is detected by means of an electric signal generated due to the change in reaction of the rotating rotor and fixed stator. A stable characteristic is maintained by making the winding even. MinebeaMitsumi’s new VR resolvers are precisely adjusted at the design stage to achieve higher accuracy. In addition, to improve resolver performance, the copper wire must be wound fast and evenly.

We applied our expertise in winding technology obtained through the motor production to the resolver, and this has made it possible to have faster copper wire winding than ever before. Our design in house advantage provides a unique opportunity to manufacture nozzles that are based on the diameter of the copper wire, turning out a tightly winded copper wire that is highly accurate and stable.

The robust design for the resolver provides incredible reliability under severe conditions, like high temperature and oil exposure.

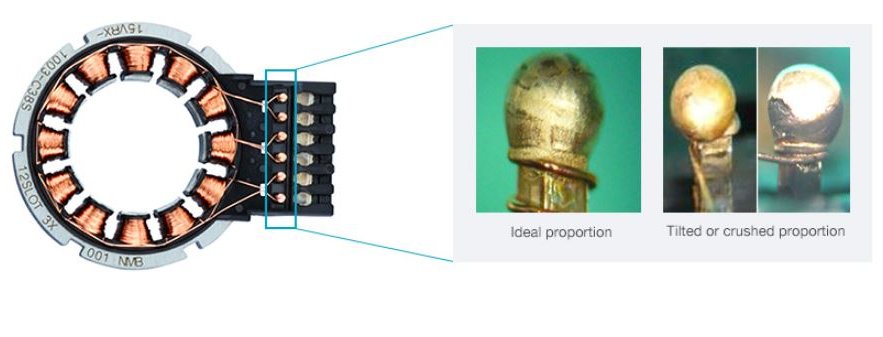

Welding technology for realizing high durability

The resolver that is directly connected to the motor requires not only high precision, but also superior durability. In developing the VR resolver, we focused on the connection between the copper wire and terminals. To enhance durability, we adopted TIG (Tungsten Inert Gas) welding instead of regular soldering. To securely connect the wire and terminals, we melt the upper part of the wire-wound terminal to make a ball shape and enfold the wire with the melted ball.

To securely connect the wire and terminals, we melt the upper part of the wire-wound terminal to make a ball shape and enfold the wire with the melted ball. This method is also advantageous since welding quality can be easily controlled by visually checking the ball shape. Defects can be easily found if the ball is bent or collapsed. To accomplish this successfully, peeling of the copper wire coating and welding must be done simultaneously, and this requires advanced technology. We have achieved highly difficult TIG welding and maintained superior durability and quality by applying our equipment condition setting technology. These solutions and technologies are offered to all our customers.

Stable parts supply by in-house production

MinebeaMitsumi manufactures many components of the VR Resolvers in house. Part production, resin forming technology, and precision stamping technology are all used in the design and manufacturing of the MinebeaMitsumi resolvers. Besides the efficient in-house production capabilities, we built a special production line for VR Resolvers in our main production base in Thailand, aiming to establish a mass production system for improving quality and supporting any sudden changes in demand. MinebeaMitsumi’s stable supply system achieved by globalization is one of our advantages.

Have a question about this product?

Ask Our Experts

Ask Our Experts