The Importance of Ball Bearing Fan

Just as the heart circulates vital oxygen and blood to parts of the body, a well-designed cooling system circulates vital cooling air to components of a personal computer.

The fan, like the heart, helps regulate internal temperature, which is fundamental to the preservation of both your body and your computer. If the internal temperature of a computer rises too high, crucial components will fail to operate properly. In fact, the fan can be thought of as the heart of any system: if the fan fails, other critical components are at risk of failure, thus leaving the entire system compromised and likely inoperable.

The “Organs” of a Computer

A computer is comprised of a set of subsystems that can be thought of as the primary “organs” required for basic functionality. These subsystems are the central processing unit (CPU), the permanent storage (disk drives), the power supply, and the temporary storage (memory.) There are many variations and function-specific components in a computer, but these are common to all and must be taken into consideration when designing a cooling system.

CPU

The CPU is normally the most heat-generating and temperature-sensitive device in the system. Microprocessor designs are characterized by rapid evolution in which higher speeds and processing capacity play a balancing act with wattage and heat generated. If the microprocessor becomes overheated, it may either shut down temporarily or become permanently damaged.

Power Supply

The power supply runs a close second to the CPU in generating heat and requiring cooling. A power supply must provide sufficient power to operate all subsystems within the system while generating a minimum of heat and consuming a minimum amount of “real estate” within the system. As with CPU’s, an overheated power supply may result in shutdown or permanent damage.

Drives & Memory

Disk drives and memory circuits also must be cooled in order to function properly. While they are not the primary heat-generating components in the system, the heat generated by other components must not be allowed to damage these key subsystems. If they are damaged, data will be lost, and the system will not operate.

Thermal Design

Just as blood circulation within a body is the key to regulating internal temperature, so air circulation within a computer is the key to cooling the computer’s vital components.

However, computer mechanical designers face the challenge of conflicting design goals – system size reduction, computing power and storage increase, quiet operation, and reliability. The key to optimizing the cooling design within these goals is the early use of thermal profiling.

The first step for a thermal designer is to perform a thermal profile. Using commercially available software, it is possible to create a graphic image of the airflow and temperature within a system chassis. These application software programs allow the designer to electronically “build” the chassis design, and select components such as CPU, power supply, and fan from a library of component profiles to install in the system. As components are added, the airflow and “hot spots” can be calculated and viewed on the screen. The designer can then modify the case design, internal component placement, or fan type in order to balance the thermal profile.

There are several different type of fans suitable for cooling a personal computer, with trade-offs in design goals associated with each one.

CPU’s may be cooled using either a passive heatsink or an active heatsink. Heatsinks for microprocessors are designed to dissipate heat through a maximum amount of surface space. A heat sink is usually placed directly on a heat source to draw the heat away from the source. Air moving across the heat sink draws the heat up and away. The more surface area available, and the better the material conductivity, the more easily heat will be disbursed.

Heatsinks for PC’s are normally aluminum, either folded fin or extrusions, with copper baseplates in order to spread the heat drawn from the CPU to the dissipating surfaces. A major goal is to achieve extremely flat contact with the processor for the best possible thermal conductivity. An active heatsink has a cooling fan attached in order to draw the hot air up and away from the heatsink.

Because these fans are placed directly adjacent to the primary heat source in the system, they themselves are subject to high levels of heat and must be designed to withstand elevated temperatures for long periods of time. Fans used for active heatsinks are normally 40mm or 60mm square axial fans with long-life ball bearings.

Power supplies also require a high-performance cooling system. Normally power supplies in personal computers use a 60mm or 80mm square axial fan placed at a right angle to the supply and against the rear on the system chassis. The purpose is to draw the hot air from the system and power supply surface out through the rear vents of the system, thus creating a front-to-rear airflow through the PC chassis. As with MPU cooling, hot air is being drawn through the fan, and the fan must be designed for elevated temperatures.

Disk drives and memory are normally cooled by virtue of the airflow, usually front-to-back, through the PC. Other vents in the front of the airflow path ensure sufficient air volume to cool memory and other specialized circuitry within the system. If needed, small axial fans or blowers may be strategically placed in the system to provide spot cooling for special circuits such as video controllers or high-speed modems.

Axial Fans

Axial fans are the most commonly used type of cooling fan, and the most economical. Sometimes called “box fans”, axial fans move air on a straight axis through the fan. Axial fans operate best under low-pressure, or low system impedance conditions. Audible noise may be kept to a minimum with axial fans by reducing the fan speed as much as possible. Because axial fans are economical and generate lower levels of audible noise, they are normally used in PC’s for both CPU and power supply cooling.

Blowers

A blower is typically used in network servers and telecommunications high system impedance (back pressure). These fans contain a circular impeller within an enclosed “squirrel cage” to provide very directed airflow under high-pressure conditions. The blower has a more concentrated airflow in which the equipment pulls air in from the sides and forces it out at a concentrated 90º angle. Blowers are also higher cost and typically generate more audible noise than axial fans.

Fan Bearing Types

We have discussed the importance of the ability for the fan itself to withstand elevated temperatures within a PC. The single most important component in determining fan longevity is the ball bearing system. Fans typically use a pair of either miniature ball bearings or sleeve bearings within the motor. Ball bearings tend to cost more than sleeve bearings, however, they withstand heat better.

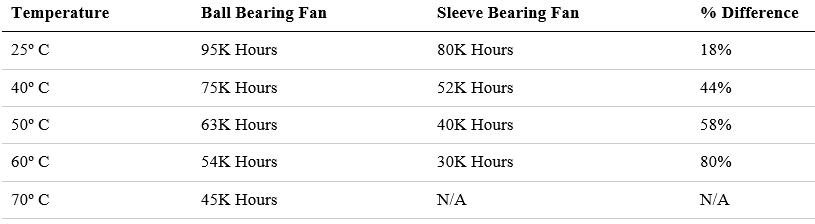

The following chart uses the L10 method to illustrate fan reliability.

L10 refers to the point of time at which 90 percent of a large population of these fan types will continue to work. On average, a fan that operates for 50,000 hours will run continuously for over 5 years. The chart indicates that when temperatures ranged from 25-60° C, ball bearing fans on average outlasted sleeve bearing fans by 50 percent. When temperatures exceeded 70° C, ball bearing fans ran for 45,000 hours, while sleeve bearing fans became inoperable. Yet, when the ambient temperatures were relatively low, sleeve bearing fans lasted as long as ball-bearing fans.

Therefore, if an application generates high levels of heat, an engineer may want to use a ball bearing fan. If the equipment generates low heat intensities, or if the equipment has a short life span, the design engineer may want to use a sleeve bearing fan.

Conclusion

In all cases when designing a cooling system, engineers must analyze cost, performance and manufacturing tradeoffs. A high-flow fan that moves air volume is not enough for a strong design. A good thermal design, the appropriate fan type, and optimal fan reliability work together to make a robust cooling system.

Changing technology, customer expectations, and striving for product differentiation among companies continue to set industry trends. For the next generation of electronic systems, whether it’s drawing cool air into a system or redirecting “toxic” hot air out of it, a well-designed fan will continue to act as the heart of your system without skipping a beat.

NMB Technologies Corporation is a MinebeaMitsumi Group company; the world’s largest manufacturer of NMB miniature ball bearings and a volume leader in the design and manufacturing of precision electro-mechanical components, backlight and LED lighting products and advanced technology solutions for smart cities, medical automotive and industrial markets.

NMB Technologies Corporation

A MinebeaMitsumi Group Company

39830 Grand River Avenue

Novi, MI 48375

USA

Tel: 248-919-2250

Email: info@nmbtc.com

Web: nmbtc.com